통합 검색

통합 검색

Issues in Existing Hatcher:

We're dedicated to advancing a range of innovative technologies in broiler raising, including but not limited to, incubators, broiler houses, big data platforms, feed management, sexing, and environmental control systems including plasma and chlorine dioxide.

Here, we'll delve deeper into the backgrounds of the crucial 'hatcher' technology, which serves as a cornerstone among these advancements.

Processes at Hatchery:

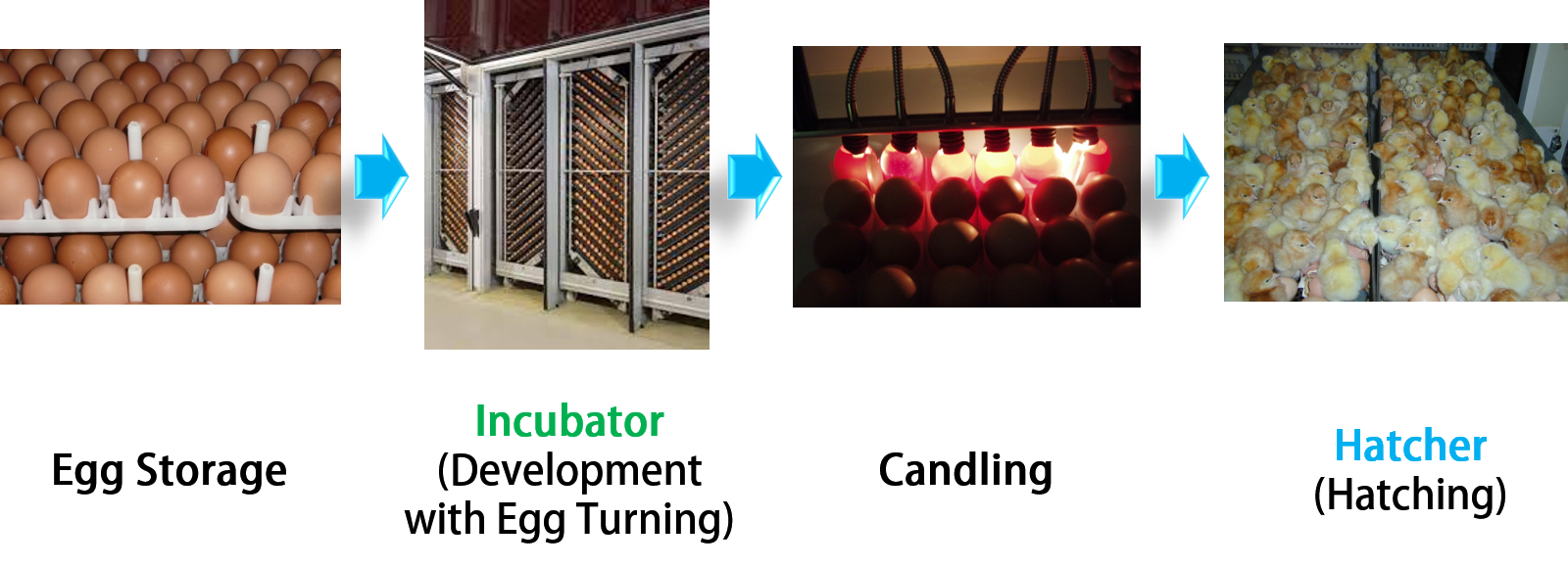

The process of hatching chicks at a hatchery begins with the importation and refrigerated storage of fertilized eggs from a breeder farm. Maintaining proper refrigeration is crucial to preserve egg uniformity throughout the transportation from laying to development. Upon arrival at the hatchery, the eggs are stored and then sequentially placed into the incubator.

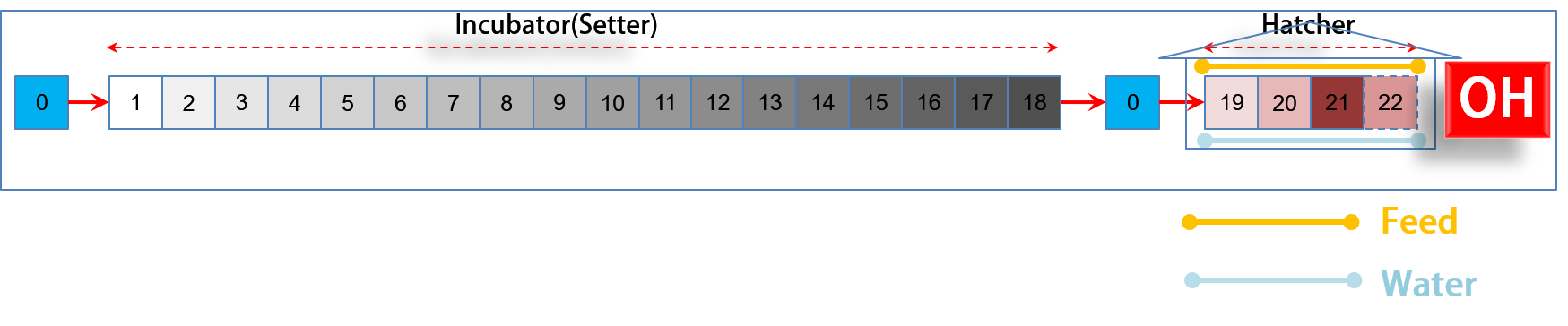

Throughout the 18-day incubation period, the eggs undergo hourly rotation to prevent embryo attachment and subsequent mortality, a process known as "turning". Once development within the incubator reaches completion, the eggs are transferred to the hatcher for the final stages of hatching. During this transfer, the eggs are illuminated to assess their internal condition, and any defective eggs are identified and removed. Historically, this assessment process was referred to as "candling" due to the use of candles.

Within the hatchery, the eggs typically hatch into chicks within approximately 3 days. Any remaining unhatched eggs are discarded, although some hatcheries may extend the incubation period by approximately a day to enhance hatching rates. Following hatching, the chicks undergo various procedures such as sexing, vaccination, grading, and packaging before being dispatched to distant broiler farms.

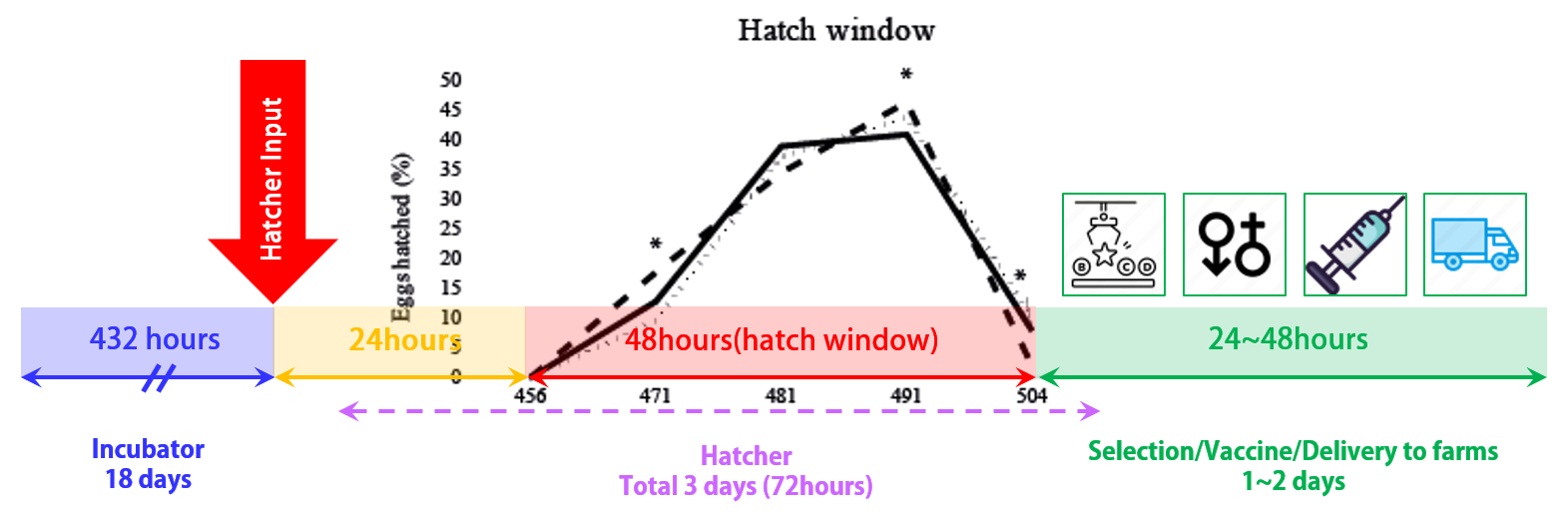

Timelines at Hatchery:

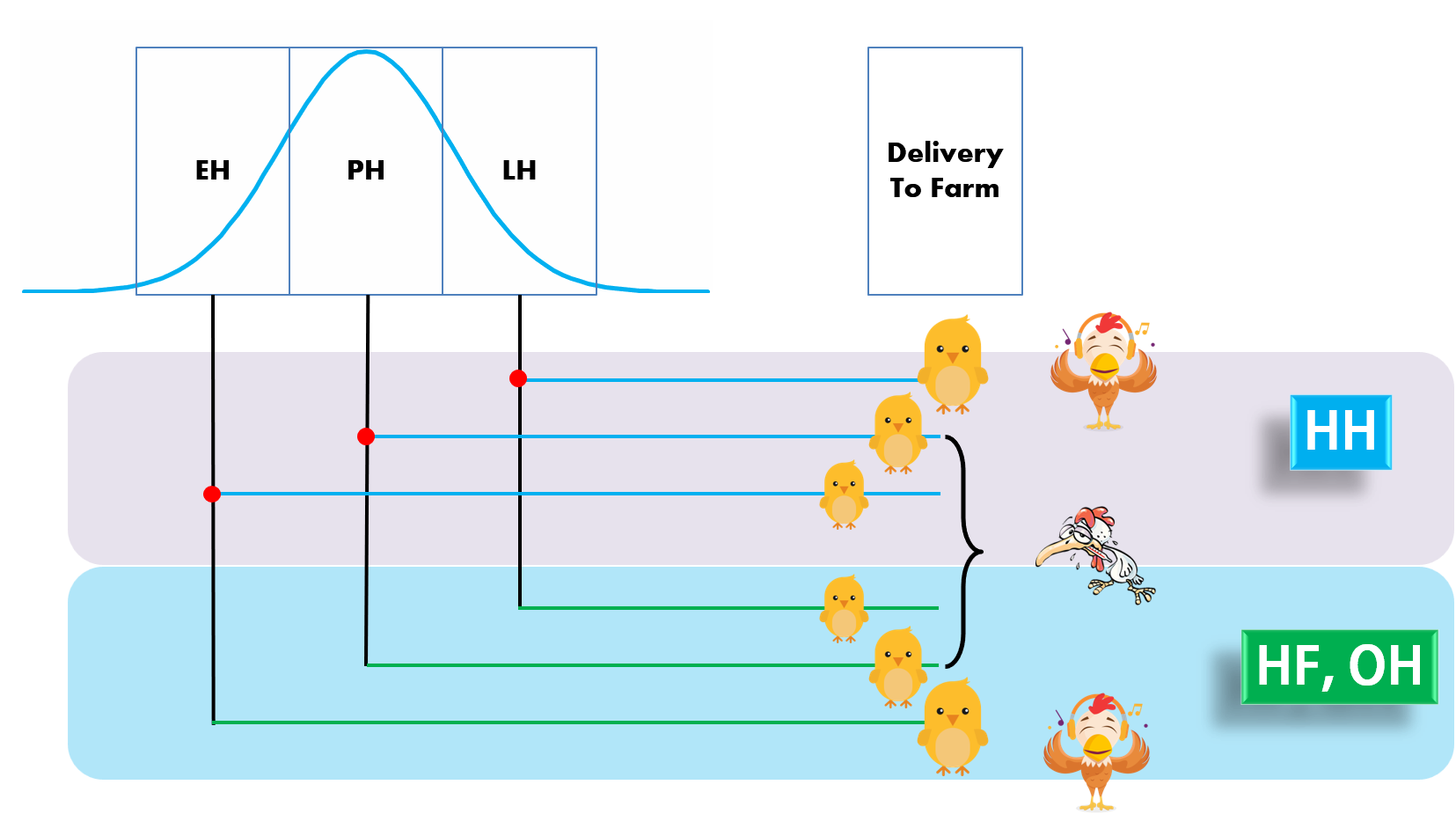

The eggs undergo 18 days (432 hours) of development in an incubator and undergo a candling process before being transferred to the hatcher. Chicks placed in egg baskets within the hatcher usually commence hatching after approximately 24 hours. The hatching process typically spans around 48 hours in total. Chicks can be categorized into early hatching (EH), peak hatching (PH), and late hatching (LH) stages. After 3 days, the incubator is opened, and the chicks are collected for further processing for delivery to farms.

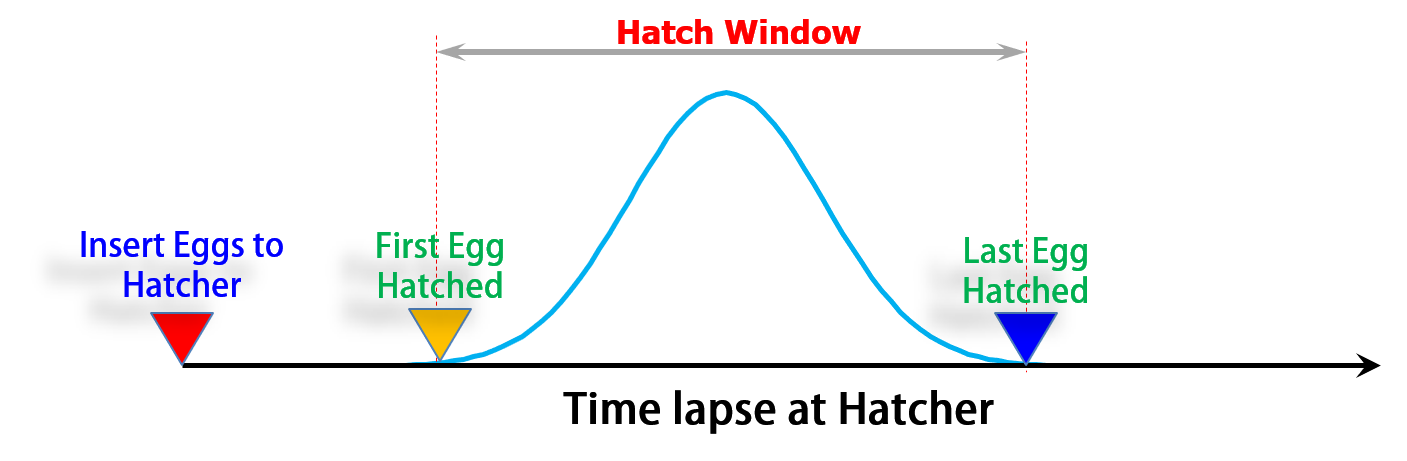

Hatch Window:

The hatch window refers to the period between the hatching of the first and last chicks. In commercial hatcheries, this interval typically ranges from 24 to 48 hours, with 48 hours being more prevalent. The significance of the hatch window lies in the fact that chicks do not have access to feed or water during this period, rendering them susceptible to starvation and dehydration, thereby resulting in immaturity of internal organs and weight loss. This can compromise their immunity and productivity later in life. Immunocompromised chicks are often subjected to prolonged transportation, lasting up to an additional 48 hours, to broiler farms, where water and feed are not provided, thus heightening the risk of dehydration and discomfort.

Starting to provide water and feed immediately upon arrival at the broiler farm may induce diarrhea and abdominal pain in chicks. Those chicks hatching early are particularly prone to starvation and dehydration, exacerbating their susceptibility to weight loss and compromised immunity.

Moreover, chicks that hatch earlier are significantly more sensitive to the changes in their environment. This is why it's challenging to ensure that all chicks are in an optimal environment simultaneously in broiler farms.

The unevenness in weight among chicks due to the wide hatch window also leads to variations in the weight of mature chickens, resulting in financial losses for the farmer.

Hence, it is crucial to minimize the duration of the hatching window. Minimizing the hatch window necessitates substantial resources and effort to maintain consistent environmental conditions for all eggs and prevent developmental disruptions during transport or storage.( https://www.youtube.com/watch?app=desktop&v=-4iKMSJes4Q&t=2s )

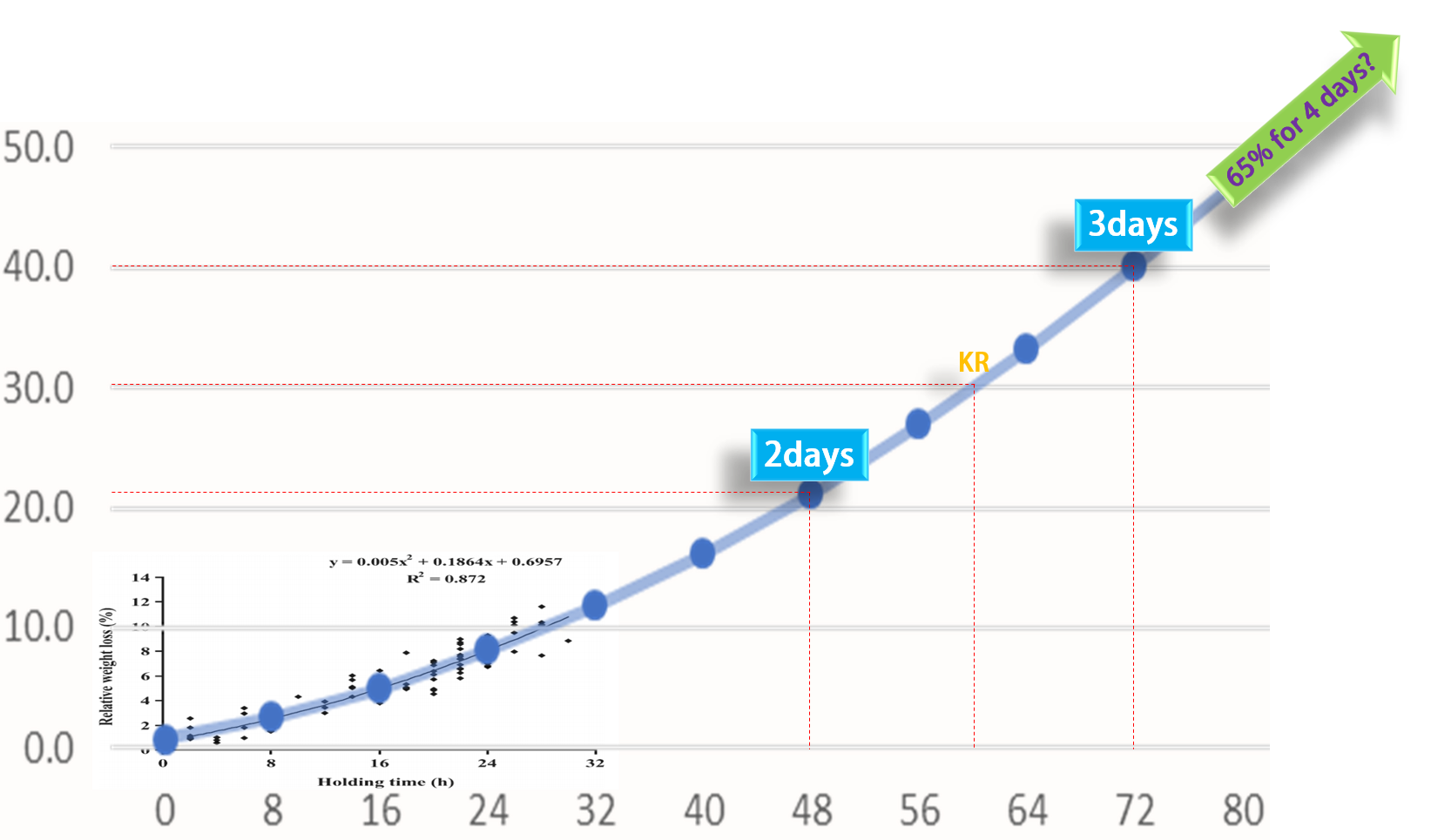

Weight loss due to dehydration:

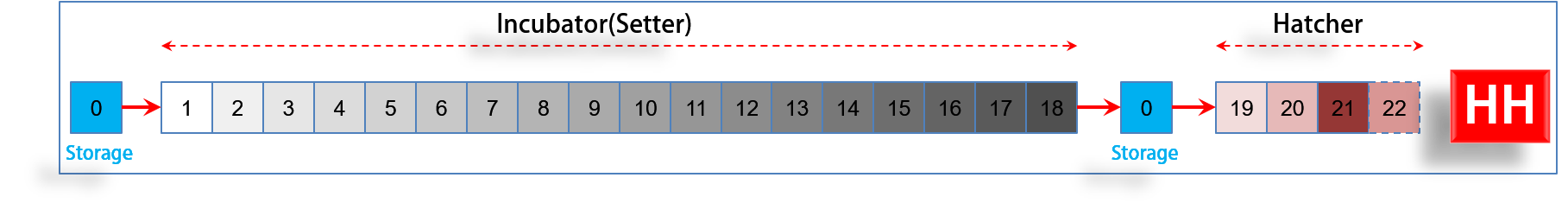

Summary of Existing Hatchery Hatch(HH):

Conventional hatching methods commonly used in the market pose notable challenges. Chicks undergo transportation to broiler farms without access to water and feed for up to 96 hours, encompassing 24 to 48 hours in the incubator and an additional 48 hours during transit. During this period, early-hatched chicks experience heightened weight loss due to dehydration and hunger.

Extended travel durations without nourishment can exacerbate discomfort, intensify motion sickness, weaken the immune system, and induce gastrointestinal issues upon arrival. This compromised state further diminishes immunity, elevating the risk of sudden death syndrome and impacting the health of adult chickens. Substantial doses of antibiotics are frequently administered via water and feed to mitigate mortality.

Moreover, hatching ages vary within the hatcher, spanning from 0 to 48 hours, resulting in chicks commencing their rearing under disparate developmental and health conditions. This variance contributes to the inconsistent quality of adult chickens. These challenges not only lead to financial losses for farmers but also directly correlate with reduced productivity.

Past efforts to solve some of the issues:

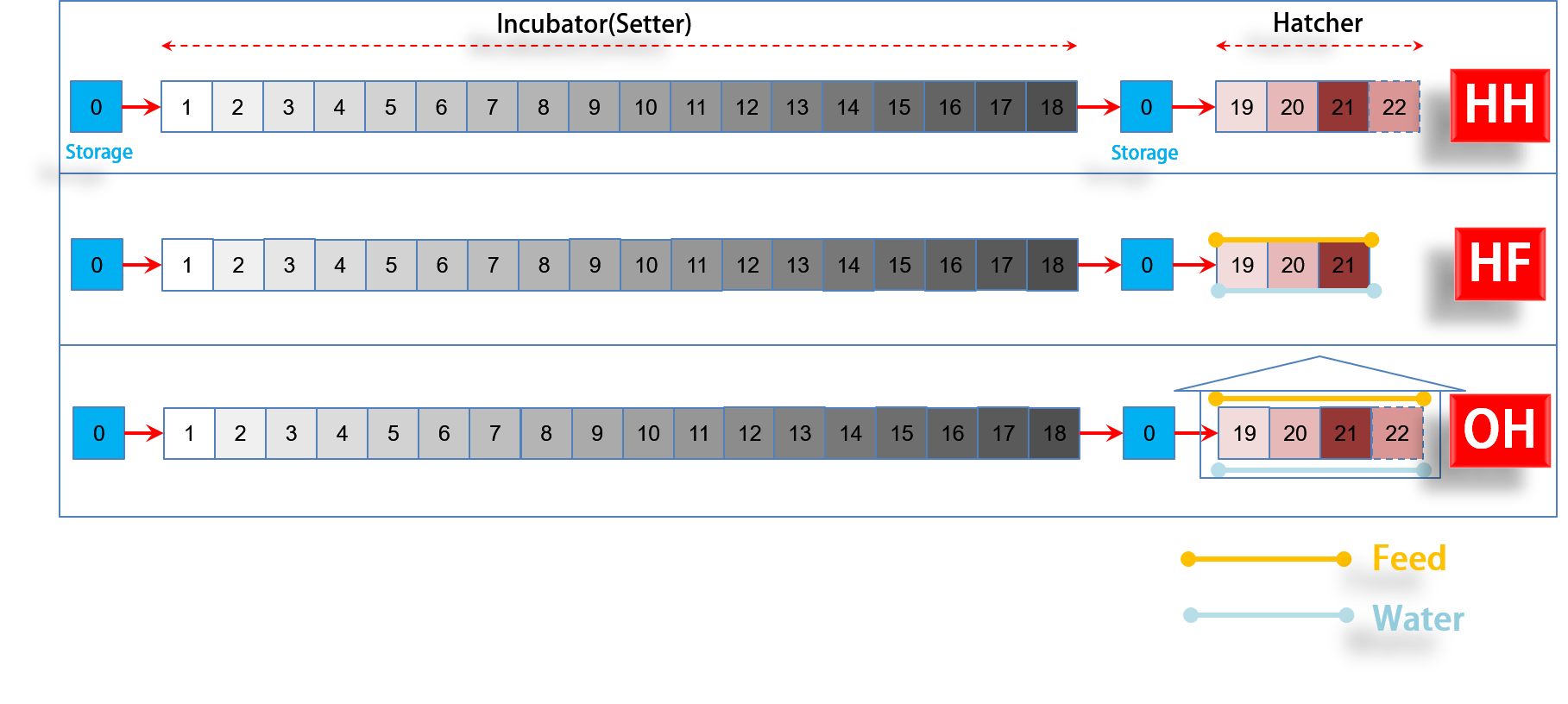

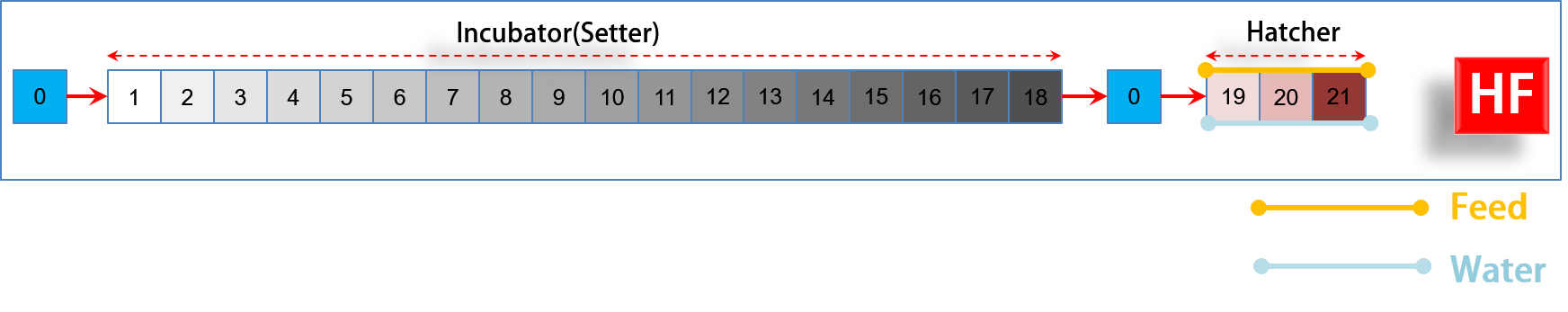

Hatchery Feeding(HF):

A method called hatchery feeding (HF) addresses the challenge of newly hatched chicks lacking access to water and feed. In this method, eggs and chick baskets are stacked within a hatcher, and the chicks that hatch from the egg basket fall into the chick basket below. These chick baskets are equipped with pre-placed feed and a water supply attached to the hatchery wall. Special devices are installed on trucks transporting the chicks from the hatchery to the breeding farm, ensuring a continuous supply of water and feed. However, a drawback of this approach is that it does not resolve the issue of growth imbalance, as chicks hatching earlier tend to grow earlier. Despite these advantages, HF technology has seen limited adoption, with only one out of over 180 hatcheries in Korea currently utilizing this technology.

https://www.poultryworld.net/poultry/hatchcare-hatcher-with-feed-and-water/

On-farm Hatching(OH):

Comparison Existing Hatchers: